We offer valves of the renowned american brands: Autotrol and Clack, as well as spare parts to these valves.

Autotrol Clack

Autotrol valves

Autotrol to is a world-renowned brand of the american company Pentair. Founded in 1963, Autotrol valves and controllers are currently produced in the US in Pisa, Italy.

Autotrol valves cover a wide range of application, either softening or filtration for residential, commercial or industrial markets, making it a brand of choice amongst water treatment professionals around the world.

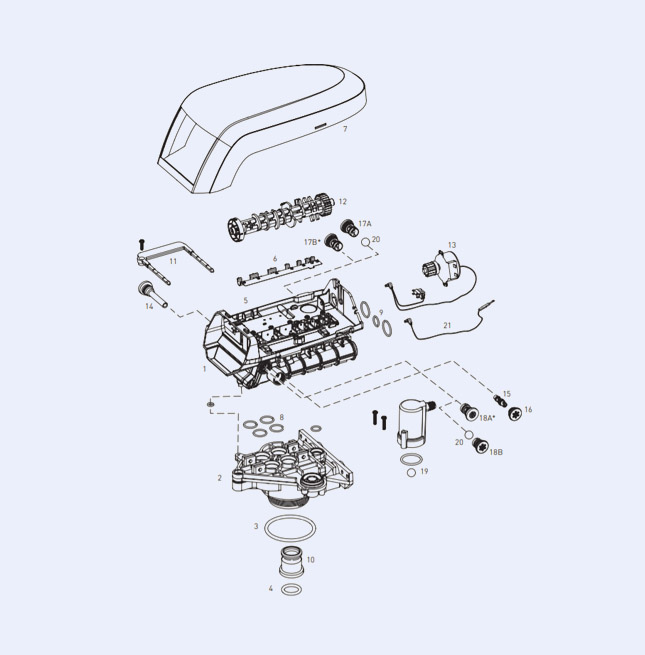

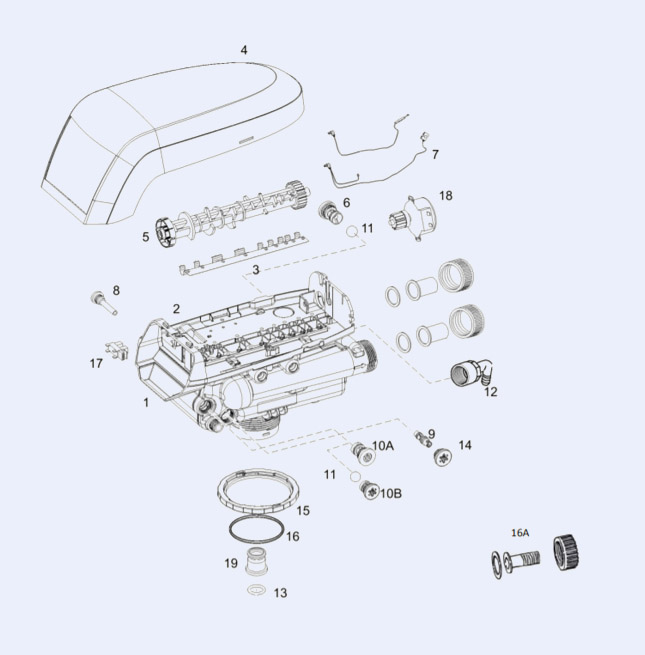

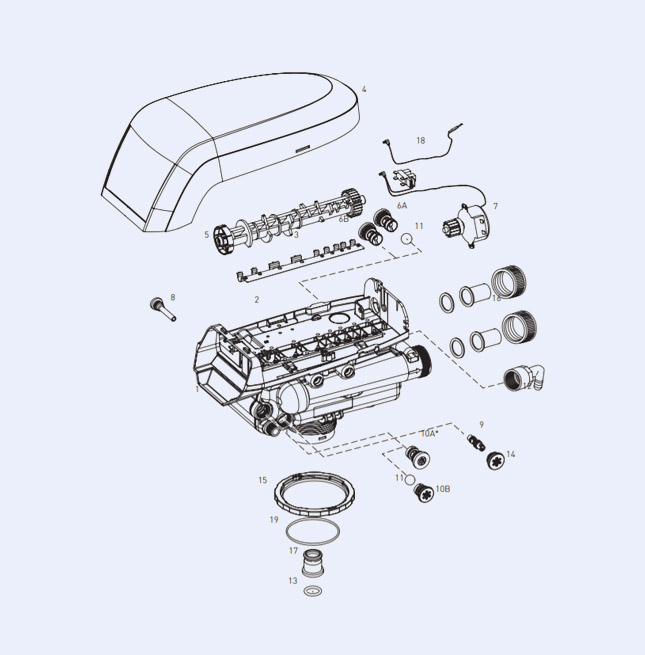

Autotrol valves are characterized by their principle of operation: flappers actuated by the cams of the camshaft. The advantage being frictionless seals, no parts subject to wear inside the valve, ease of maintenance, longer service intervals and longer life cycle of the valve.

All Autotrol valves have been certified by major EU certificates: CE, 206 / 95 / EC low voltage, 2004 / 108 / EC electromagnetic compatibility, ACS, WRAS and DM174. On top of that, the manufacturers’ plant is ISO 9001: 2015 certified.

|

Residential/ Commercial |

Commercial/ Industrial |

||||

|

368 |

255 Logix |

Performa (263/268) |

Performa CV (273/278) |

Magnum |

|

|

Valve material |

Glass Filled Noryl |

Glass Filled Noryl |

Glass Filled Noryl |

Glass Filled Noryl |

Glass Filled Noryl |

|

Inlet/ Outlet |

3/4, 1” |

1/2, 3/4, 1”, 22 mm, 32 mm |

3/4, 1”, 22 mm, 32 mm |

3/4, 1”, 22 mm, 32 mm |

1 1/2” (Magnum Cv), 2” (Magnum IT) |

|

Service flow rate (m3/h / gpm) |

3.8/16.6 |

3.5/15.5 |

5.7/25 |

5.7/25 |

17.3/76 (Magnum Cv), 18.2/80 (Magnum IT) |

|

Backwash flow rate m3/h / gpm |

0.6/2.73 |

1.4/6 |

4.5/20 |

4.5/20 |

20.2/89 |

|

Maximal softener tank size |

10” |

14” |

14” |

21” |

42” |

|

Filter tank size |

6-24” |

N.A |

6-24” |

6-24” |

14 – 36” |

|

Regeneration type |

Downflow |

Downflow |

Downflow/ Upflow (269) |

Downflow |

Downflow |

|

Adjustable cycles |

|

|

|

|

|

|

Duplex |

|||||

|

Multiplex |

|||||

|

Drain connection |

½” |

½”, 3/8” |

¾” |

¾” |

1 ½” |

|

Brine line |

3/8” |

3/8” |

3/8” |

3/8” |

½” |

|

Riser tube height (from the top of the tank) |

13 +/- 13 mm |

29 +/- 3 mm |

13 +/- 13 mm |

13 +/- 13 mm |

6 +/- 9 mm |

|

Riser tube size |

1.05” |

1.05” |

1.05” |

1.05” |

1.5” |

Controller versions

Flow meter (volumetric) version - with measurement of water consumption – regenerations take place according to the actual water consumption with keeping the reserve until the set time of regeneration. It is a more economical (regarding operating costs) and recommended version.

The controller in a flow meter version has the following functions:

- memory backup;

- cycle length adjustment;

- instantaneous flow indications;

- indication of the amount of water remaining until the next regeneration.

Time clock version – without the measurement of water consumption – regenerations take place at a set time, regardless of water consumption.

Clack Valves

Clack is a renowned brand of the Clack Corporation. Clack Corporation was established in 1946. The Clack valves and controllers are manufactured in the US.

Clack valves cover a wide range of application, either softening or filtration for residential, commercial or industrial markets, making it a brand of choice amongst water treatment professionals around the world.

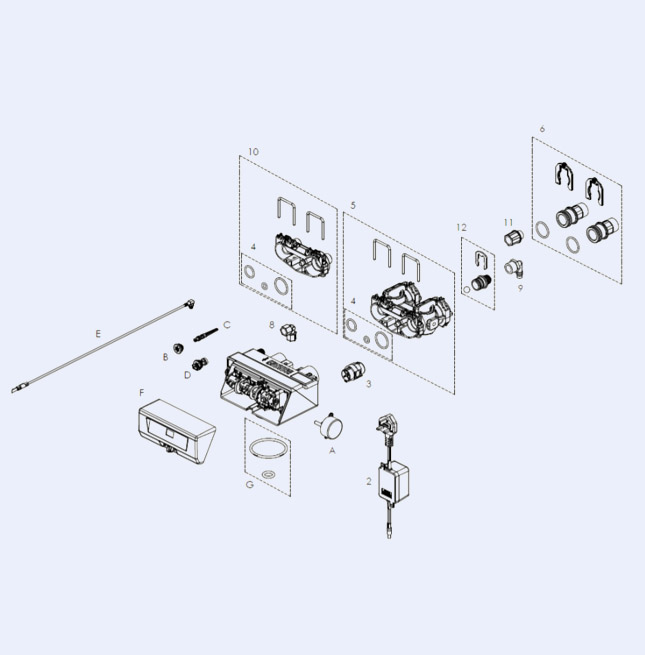

Clack controllers:

- CI version with five buttons, which provides diagnostic functions with the option of connecting a water meter and adjusting cycle length and cycles order

- EI version with four buttons, without diagnostics, with the option of connecting a water meter and adjusting cycle length

- TC version with three buttons, without diagnostics, without the option of connecting water meter and with no possibility of changing cycle length

- version with color display and Polish menu, which provides diagnostic functions, with the option of setting service alarm and service data, with the possibility of connecting the water meter and with the option of adjusting cycle length and cycles order

Valve versions:

We sell valves in three variants:

- time clock version

- flow meter version

- mixing version

|

Residential/ Commercial |

|||

|

SPECIFICATION |

WS 1 |

WS 1.25 |

WS 1.5 |

|

Service Flow ∆p 1 bar Backwash ∆p 1.7 bar |

102 lpm (6.1 m3/h) |

129 lpm (7.7 m3/h) (34 gpm) 121 lpm (7.3 m3/h) (32 gpm) |

265 lpm (15.9 m3/h) (70 gpm) 197 lpm (11.8 m3/h) (52 gpm) |

|

Tank Applications: |

6” - 24” |

6” - 24” |

12” - 30” |

|

Inlet/Outlet Fitting Connections |

0.75” - 1.25” BSPt |

0.75” - 1.25” BSPt |

1.5” BSPT |

|

Valve Material |

Noryl |

Noryl |

Lead Free Bass |

|

Cycles |

Up to 9 (CI) / Up to 6(EI, TC) |

Up to 9 (CI) / Up to 6(EI, TC) |

Up to 9 (CI) / Up to 6(EI) |

|

Regeneration |

Downflow/Upflow (CI) Downfload (EI, TC) |

Downflow |

Downflow |

|

Operating pressures |

1.4 - 8.6 bar |

1.4 - 8.6 bar |

1.4 - 8.6 bar |

|

Operating Temperatures |

4° - 43° C |

4° - 43° C |

4° - 43° C |

|

Meter: Flow Rate Range Volume Range (cubic meters) Totalizer |

1 - 102 lpm (0.06 - 6.1 m3/h) Yes |

1 - 129 lpm (0.06 - 7.7 m3/h) Yes |

2 - 284 lpm (0.12 - 17.0 m3/h) Yes |

|

Distributor Pilot |

1.05” O.D. Pipe |

32 mm O.D. Pipe |

50 mm O.D. Pipe |

|

Drain Line |

3⁄4” Standard (1” Optional) |

3⁄4” Standard (1” Optional) |

1.25” FPT with ¾” Standard (1” Optional) |

|

Brine Line |

3⁄8” or 1⁄2” O.D. Poly Tube |

3⁄8” or 1⁄2” O.D. Poly Tube |

½” oraz 5/8” O.D. Poly Tube |

|

Mounting Base Options |

2.5” - 8 NPSM |

2.5” - 8 NPSM |

4” – 8” UN |

|

Height From Top of Tank |

187 mm |

187 mm |

191 mm |

|

Shipping Weight w/Meter |

2 kg |

2 kg |

9.5 kg |

|

Electrical: Supply Voltage Supply Frequency Output Voltage Output Current |

230V AC50 Hz12V AC500 mA |

230V AC50 Hz12V AC500 mA |

230V AC50 Hz12V AC500 mA |

|

Industrial |

|||

|

SPECIFICATION |

WS 2 |

WS 2 H |

WS 3 |

|

Service Flow ∆p 1 bar Backwash ∆p 1.7 bar |

435 lpm (26.1 m3/h) (115 gpm) 303 lpm (18.2 m3/h) (80 gpm) |

473 lpm (28.4 m3/h) (125 gpm) 473 lpm (28.4 m3/h) (125 gpm)9 |

946 lpm (56.8 m3/h) (250 gpm) 833 lpm (50.0 m3/h) (220 gpm) |

|

Tank Applications: |

12” – 48” 12” – 26” |

16” - 63” 18” - 63” |

18” - 96” 18” - 63” |

|

Inlet/Outlet Fitting Connections |

2” BSPT |

2” BSPT 2.5” Groove lock |

3” BSPT |

|

Valve Material |

Lead Free Bass |

Lead Free Bass |

Lead Free Bass |

|

Cycles |

Up to 9 (CI) / Up to 6(EI) |

Up to 9 |

Up to 9 |

|

Regeneration |

Downflow |

Downflow |

Downflow |

|

Operating pressures |

1.4 - 8.6 bar |

1.4 - 8.6 bar |

1.4 - 8.6 bar |

|

Operating Temperatures |

4° - 43° C |

4° - 43° C |

4° - 43° C |

|

Meter: Flow Rate Range Volume Range (cubic meters) Totalizer |

5.7 - 568 lpm (0.34 - 34.1 m3/h) 0.02 - 5700 m3 Yes |

5.7 - 473 lpm (0.34 - 28.4 m3/h)0.04 - 3796.2 m3 Yes |

13 - 1325 lpm (0.78 - 79.5 m3/h)0.04 - 3796.2 m3 Yes |

|

Distributor Pilot |

50 mm O.D. Pipe |

63 mm O.D. Pipe |

90 mm O.D. Pipe |

|

Drain Line |

1.5” NPT |

2” BSPt 2.5” Groove lock |

3” BSPt |

|

Brine Line |

1.5” NPT or Polytube ½” |

1” NPT or Polytube ½” |

1” NPT or Polytube ½” |

|

Mounting Base Options |

4” – 8” UN |

4” – 8” UN 6” – Flange or Side Mount |

6” – Flange or Side Mount |

|

Height From Top of Tank |

216 mm |

280 mm |

311 mm |

|

Shipping Weight w/Meter |

13 kg |

23 kg |

26 kg |

|

Electrical: Supply Voltage Supply Frequency Output Voltage Output Current |

230V AC50 Hz12V AC500 mA |

230V AC50 Hz12V AC500 mA |

230V AC50 Hz12V AC500 mA |