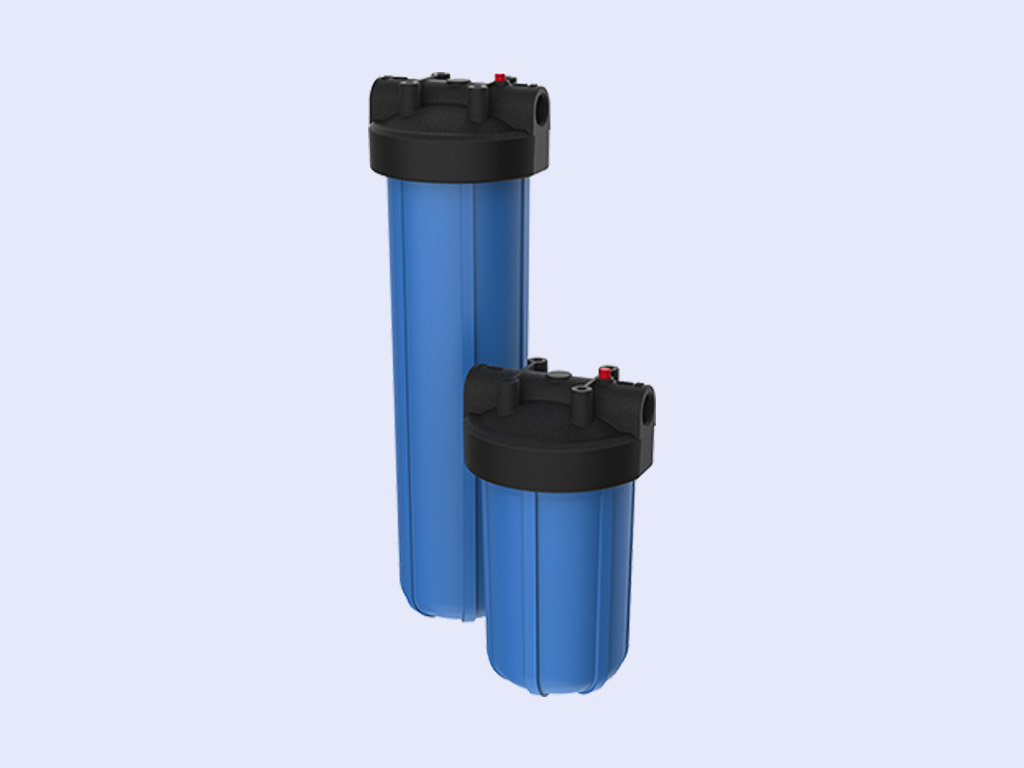

In-line filters

Usually, in-line filters constitute the first stage of water treatment which is also called pre-filtration or mechanical filtration. They are used to remove any suspensions and solids such as: rust, silt, metal filings, clay and sand. This is how the further part of installation and other water treatment devices are protected against mechanical damage and silting.

Cartridges

An in-line filter consists of a body (10” or 20” as standard) and replaceable cartridges with various properties. Therefore to achieve optimal treatment results, treatment systems sometimes use a series of filters with cartridges lined up in the correct order:

- pleated cartridges

- string wound cartridges

- polypropylene cartridges

- carbon cartridges

- strainer cartridges

Download PDF:

Cintropur filters

Especially for industrial purposes, we also sell reusable in-line filters from a Belgian brand Cintropur. Cintropur water filter is efficient, durable, reliable, and easy to clean and does not cause high pressure drops. It has a transparent casing and a unique filtering sleeve system.

CINTROPUR® offers a double-stage of filtration concept. First, the water flow from the inlet is directly transformed into a centrifugal spin forcing the larger particles down into the lower bowl. The next stage of filtration is achieved by the exclusive filter sleeve, available in different finenesses ranging from 5 up to 300µ.

They are equipped with transparent casings enabling a visual evaluation of the degree of cartridge contamination. Cintropur water filters are single-stage devices but it is possible to simultaneously connect a few filters in series or in parallel.

Download PDF: